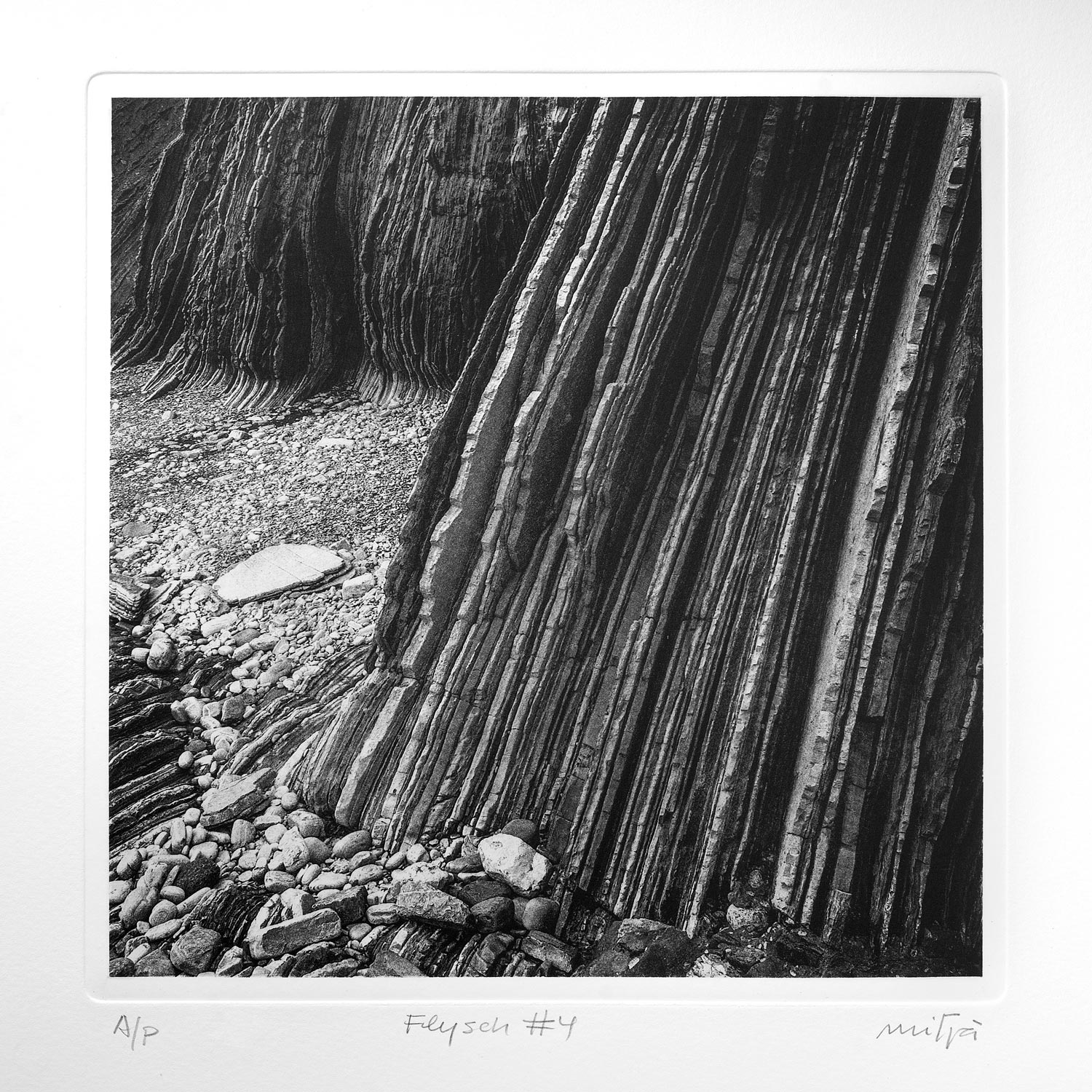

– Photographer & Printmaker –

A Hybrid Place About Early Photography and Digital Imaging

Esta es la web de Carles Mitjà, Fotógrafo y Heliograbador. En ella encontraréis una muestra de su trabajo así como entradas dedicadas a las técnicas empleadas, tecnología de cámaras, procesado de imágenes y algunas reflexiones sobre la imagen fotográfica.

This is the website of Carles Mitjà, Photographer and Printmaker. Here you will find a sample of his artwork as well as posts dedicated to the employed techniques, camera technology, digital image processing and some thoughts about photographic imaging.